Custom Cloud Solutions and Savings: How KGPCo’s White Box Solution Delivers Both

June 29, 2021

KGPCo’s White Box solution can help deliver a first-class experience to end users while reducing Service Provider equipment expenditures.

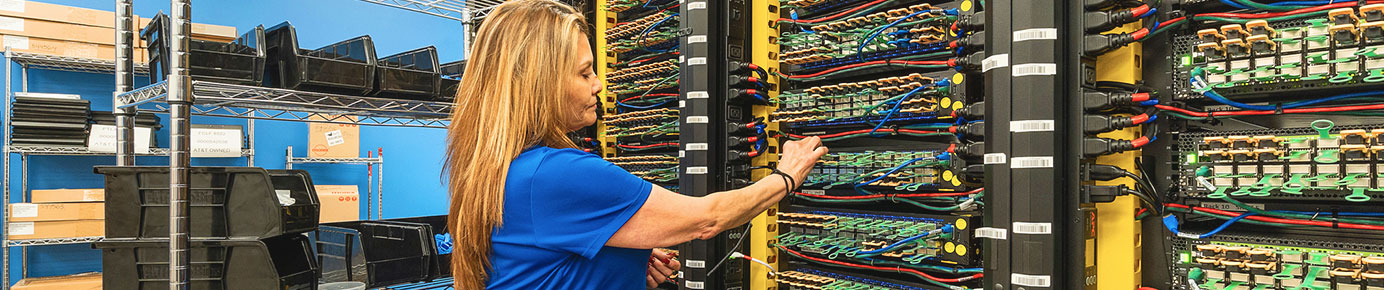

Soon after KGPCo entered the Cloud communications space, we built a state-of-the-art Solution Innovation Center in Irving, Texas. It is here that we design and build sophisticated solutions for Tier 1 and Tier 2 Service Providers that deliver significant equipment cost savings for them and leading-edge experiences for their Customers.

For an in-depth overview of KGPCo’s Cloud operations, we sat down with our Chief Strategy Officer, Peter Wraight.

How would you characterize KGPCo’s role in Cloud?

Our primary role in Cloud is to provide a solution to our Customers that allows alternative hardware to be used with their current software or other related software. We often use the term White Boxes. Basically, White Boxes are products without an OEM label.

Does KGPCo aim to move Customers to a White Box environment?

Yes. Today, KGPCo’s goal in Cloud is to help our Customers adapt to the White Box environment. We take software, develop the interface to be utilized in new White Box hardware and sell a lower cost option to our Customers.

Do Original Equipment Manufacturers (OEM) have a role in this process with KGPCo?

We partner with a lot of OEM’s because when the White Box is built into a stack of product, we can incorporate OEM equipment as well as our own White Boxes. We have the option to purchase OEM boxes and build the stack with OEM products.

So, this process of KGPCo integrating the White Box and other OEM equipment, plus the software means KGPCo is a System Integrator?

Yes. What we do as a System Integrator is take disparate parts, put them together, and integrate them in a way that can be used as a finished solution. We integrate and test; we make sure that the software is working, and everything is happening as it should through that stack of equipment. Then, we prepare for it to be tested in an environment similar to which it will be deployed. We reassemble the stack of equipment and make sure everything is working properly.

Is there more to the complete integration process?

It is a complex process. The first stage is site development. Our service team goes to the Customer’s location, conducts a site survey and creates a site plan to ensure that what we build will fit the specs of where it will be installed, and that the conditions of the site are adequate for the equipment needs. Then, we design the solution. Our engineers take the separate software and hardware components and put them together, ensuring it works as it should in the environment for which it was designed.

Next, and crucial to the process, we write a set of operating instructions so that once the script is initiated it can load the White Box automatically and record the physical and virtual attributes. Following that, our integration team retests the product in a mock production environment. When testing has been completed, the team prepares each piece for final deployment, and it is ready for our Customer. In many cases, our deployment team installs the equipment on site for the Customer.

Does KGPCo offer maintenance after we have installed a system?

Yes, we offer our Customers the option to purchase a Maintenance Support Contract, much like consumers get with most OEM electronics.

Is the integration of separate hardware and software common?

No, it is not. Many companies sell the hardware and software together as one. In our industry, the way we create a White Box solution is fairly uncommon. It is not as easy as taking two pieces and putting them together, we have to design and build an operating experience.

How can a Customer benefit from a White Box?

Primarily, it provides a significant cost savings. A savings to the Customer directly, and a savings in the market. When brand names are stripped from components and instead, we use our generic White Box and marry it with software designed exactly how the Customer needs it, and nothing more, it can offer a significant savings. It also helps to drive down the costs and gives our Customers a solution that meets their needs without the added cost of attributes they do not need.

What challenges might arise in the process?

Because we are taking parts that were not specifically made for each other, it can be challenging and time-consuming to re-design the two parts to work as one. Most of what we build is customized which can lead to challenges in designing a solution from one Customer to the next. But, in the end, once we have written the code to integrate the software and hardware, we are able to provide our Customers with a product that is significantly less expensive than an equivalent OEM box.

Is every one of KGPCo’s Cloud solutions custom-built?

Almost everything we do is customized. We design our White Box solutions around what the Customer needs. Depending on the level of customizations, we may not be the best fit for every customer, but our White Box solutions meet about 90% of the market needs for approximately half the cost of the typical OEM product. It is becoming more common that a solution we design for a customer is then standardized for all of their White Boxes on that one solution, which provides a continued cost savings for them and ease of process for us.

What is the next step for KGPCo as a White Box Integrator?

We want all of our Customers to know that we offer customized White Box solutions to fit their needs.

Interested in learning how KGPCo’s White Box solution can help you deliver first-class experiences to your customers while reducing your equipment expenditures? Contact us to begin a consultation.